Transforming Waste into Value: The Process of Coconut Shell Activated Carbon

Coconut shell activated carbon has been dominating the activated carbon market over the years. And its wide industry usage such as wastewater treatment, drug delivery, and fabrication purposes render it a vital substance in the diverse industrial market.

One may find a coconut-based AC manufacturer easily but the game lies in its meticulous manufacturing methodology which only pioneers like Suneeta Carbons practice. To know further about its manufacturing process and applications read through this article.

Coconut-based AC is a primary type of AC with highly porous, enhanced hardness and filtration potential. Through meticulous processing and carbonization, coconut shells can be transformed into activated carbon with adsorption competencies and other unique properties. Therefore, its utilized in nuanced industrial sectors as mentioned above.

Since coconut shells are a naturally occurring resource, coconut shell activated carbon is also considered an eco-friendly choice.

Moreover, its porous structure allows flawless adsorption of organic substances, impurities and gases dissolved in water, rendering its diverse industrial applications.

The Manufacturing Process: Activate Carbon from Coconut Shell

Over the years, coconut shell has been identified as a promising feasible alternative to biomaterial for the production of charcoal. So, a standard manufacturer first gathers the raw material from agricultural industries or coconut processing plants and then takes it to the next step i.e. crushing and grinding.

Post that, the activated carbon preparation from coconut shells is a two-step methodology with involves- (a) carbonization and (b) activation.

Carbonization is the process of transforming the residual matter into a useful substance through a heating process (in the presence of an inert atmosphere) i.e. pyrolysis. The appropriate temperature is 500 degrees where better charcoal is obtained for commercial purposes with high percentage removal of volatile matters. In the manufacturing process of coconut shell steam activated carbon, a temperature range of 900 to 1100 degrees is to be maintained. Certain chemical reactions between steam and carbon happen on the internal surface of the carbon. This process can seamlessly alter pore sizes and deliver carbon-customized results for particular applications.

That’s not all about making activated carbon from coconut shells in the competitive market. Standard manufacturers carry out the final yet necessary steps that involve meticulous washing, then drying, sieving, and lastly packaging. And each of these steps has its own uniqueness which best describes the overall quality of the resultant activated carbon.

Applications of Coconut Shell-based Activated Carbon

- Medical devices and drugs: In the medical devices sector, its high adsorption capacity is implemented to adsorb toxins, alleviating symptoms. This type of AC is also used as an anticancer agent. It is evident that synthesized carbon nano-tube has been a substantial material for cancer diagnosis.

- Drinking water: It is vehemently used in treating drinking water. It optimizes the color, odor, and taste by eliminating organic compounds, heavy metals, and other pollutants in it. With its excellent porous structure comprising of microporous molecular structure (above 80%) coconut shell activated carbon meticulously adsorbs impurities.

- Beverage and Food Industry: This type of AC is also applied as a decolorizing agent in the food and beverage industry to eliminate odor, color, and undesirable taste.

- Support for Catalysts: Since coconut shell-activated carbons have significant physical and chemical features (like high surface area and chemical balance), it’s used as a support for catalysts worldwide.

- Wastewater Treatment: Just like drinking water treatment, coconut shell-based AC is also incorporated to treat wastewater (both for government and commercial purposes). It helps in the elimination of organic matter, deodorization, pH adjustment, decolorization, and microbial inhibition.

Conclusion

Even with these insights furnished above, several businesses ask whether coconut shells will be a better alternative than traditional activated carbon and solve their purpose. The answer is an easy yes! If you buy it from a standard manufacturer, you will get high-quality AC with unmatched adsorption capability.

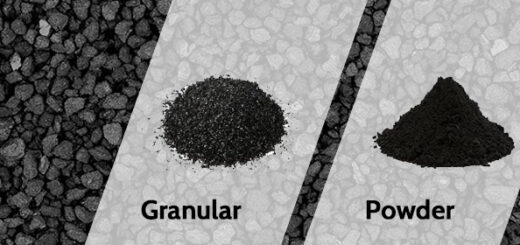

Suneeta Carbons pioneer in the manufacturing of coconut shell-based activated carbon. Our final products (inclusive of coconut shell granular activated carbon and others) surpass every BIS standard testing and come with unparalleled packaging. This makes us the go-to exporter of activated carbon worldwide.