Applications of Activated Carbon

Definition of Activate Carbon

Activated carbon, in other terms- activated charcoal/activated coal is a very effective adsorbent. Due to their commendable pore structure (macro, meso, and micro) pores, surface area, and a high degree of surface reactivity, they can be utilized to dechlorinate, filter, deodorize, and decolorize both vapor and liquid applications.

For your understanding of its market in India- The fundamental materials for activated carbons are wood, coconut shell, and coal and Suneeta Carbons happens to be a renowned exporter and manufacturer of high-quality activated carbons.

Prominent Applications of Activated Carbon

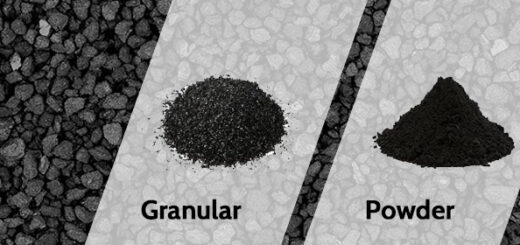

Well, since its inception during the late 3000 BC, the applications of activated carbon have changed and now it’s been utilized based on its different textures. The types are given below: –

- Powdered activate carbon

- Granulated activated carbon

- Pelletized activated carbon

- Impregnated activated carbon

- Catalytic activated carbon

While powdered, granulated, and pelletized as commonly known to you, catalytic activated carbon is produced by modifying the surface structure and impregnated carbon also gets deduced from the same method with the implications of chemicals and metal particles on its surface.

Kindly note that each size and grade of activated carbon is application-specific. Choosing the appropriate activated carbon product and mesh size depends on the application and pollutants you want to eliminate.

A gas adsorption analysis informs that one gram of activated carbon has more than 3000 m2 surface areas because of its high amount of microporosity that can offer a high activation level for practical application. Some prominent applications are given below-

- Removing pollutants from aqueous solution and the atmosphere.

- Waste-water purification

- Food grade goods

- Cosmetics

- Automotive applications

- Industrial gas purification

- Petroleum

- Precious metal recovery, essentially gold

Developing a perfect activated carbon filtration system with ample pressure drop, contact time, and vessel size is crucial. Also, the activated carbon’s architecture (chemical and physical characteristics) plays a crucial role in eliminating pollutants effectively. Therefore, material testing is vital and ASTM test methods such as surface area, density, moisture content, and butane activity can be carried out to find the best suitable material for your utilization.

Now let us venture into the types of activated carbon in depth and their respective application-

- Coconut shell based activated carbon– This has a very steep hardness level and is more abrasion-resistant than any other type. It is known for its high density of micropores (> 80%) which can actively absorb impurities such as those present in drinking water. Its wide range of applications include-

- Portable water purification

- Gold absorption from gold solution

- Medical

- Catalyst support

- Coal based activated carbon- Its preparation has two steps- (a) carbonization of the activated carbon raw material at high temperature, without the presence of oxygen, and (b) to activate the material that is created from the carbonization process to come up with a more structured pore formation. Its applications include-

- Industrial air purification

- Wastewater treatment

- Purification of food and beverage

- Chemical purification

- Medical and automotive uses

- Wood based activated carbon– This type is manufactured from particular forms of sawdust and wood. This typical carbon is produced by either phosphoric acid or steam activation. It is ideal for decolorization of liquids because of its high density of meso and macro pores. Typical applications are-

- Pharmaceutical Industry

- Decolorization and purification of edible oil

- Wastewater and surface water treatment